In order to test the service life of our products under the designed service and maintenance situation and predict or validate the weak parts product, we use three testing methods, 4000 thermal cycling testing, 2400 flow impact testing and 300h heated constant speed testing.

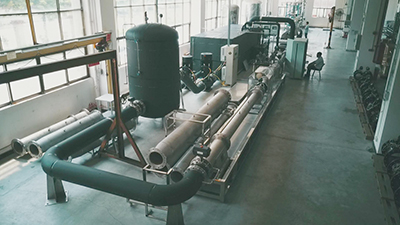

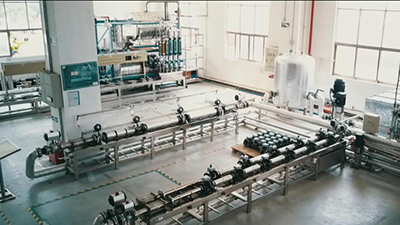

The heat meter testing equipment consists of a flow meter, inflow and outflow thermometer, integrator and some other accessories. The computer on the test platform can read the real-time data of the inflow thermometer, outflow thermometer and electromagnetic flow meter, acquire temperature difference and flow parameters, and calculate the amount of heat exchange produced by heat exchange system according to energy integral operation based on the thermodynamic formula.

Basic Controls uses three thermostatic water sinks - low temperature 6° water sink, medium temperature 50° water sink and high temperature 90° water sink - to examine and standardize the error between display temperature and real temperature.

By examining power meters with the same specifications, different constants and different communication protocols, we can test creeping, enablement, fundamental error, standard deviation, constant and daily timing error according to the testing regulations.

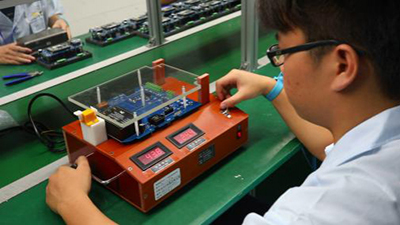

Basic Controls uses PCB testing equipment to test various performances of the circuit board.

The flow testing equipment can be used to test the metering accuracy of energy, temperature and flow of some products with large caliber, such as DN250-DN400, DN125-DN200 and DN50-DN100, and calculate the amount of heat exchange of the heat exchange system.

Guangzhou Basic Intelligence Technology Co., Ltd.

Add.: No. 164, Jinyang 1st Road, Jinhu Industrial Zone, Tanshan Village, Hualong Town, Panyu District, Guangzhou City, Guangdong Province

Contact: Sara

Fax: +86-20-80672831